|

Image 1 of 13

|

|

How do you move five tonnes across a factory floor safely and easily? Here’s how: add an MR motorized trolley to your Kito ER electric hoist and you’ll increase productivity and decrease unwanted movement so you can easily direct your load. Opt for an adjustable two-speed unit with a variable frequency drive (VFD) and you’ll also be able to set your speed preference and ensure super smooth starts and stops every time.

*MR Trolleys can only be used with ER Hoists.

EASY ACCESS SUSPENSIONQuickly change from hook to lug for trolley mount configurations on most models. The MR trolley’s external suspension pins allow you to make rapid modifications if needed. |

|

|

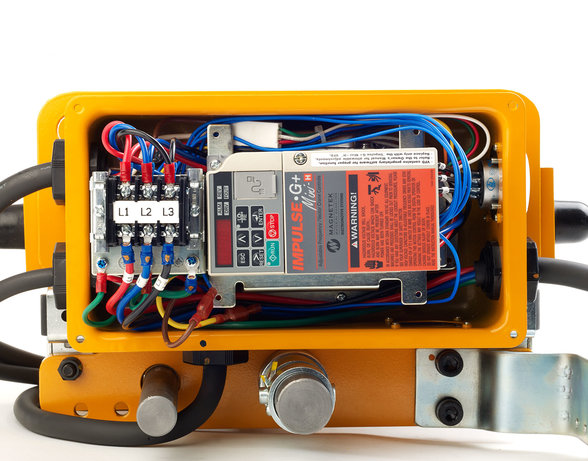

Adjustable Two-Speed TrolleysGet excellent traversing motion and load control with a variable frequency drive (VFD). The MR trolley’s programmable VFD provides gradual starts and stops to reduce unwanted movement while travelling. |

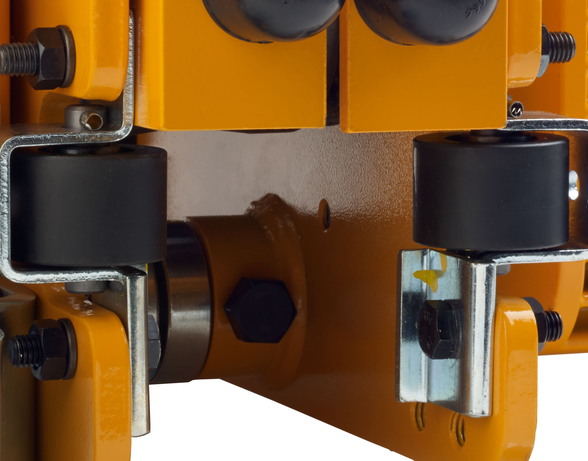

Innovative Side-Guide Roller SystemDesigned for very smooth travel along the beam, the MR motorized trolley uses an innovative side-guide roller system that keeps the load controlled and on track while traversing. |

|

|

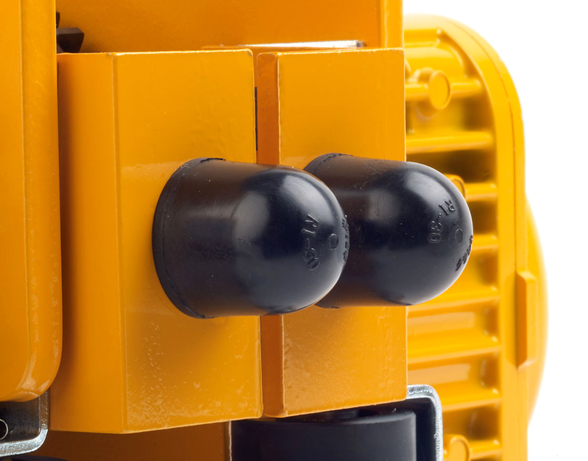

Drop Stops and Rubber BumpersDrop stops and rubber bumpers not only provide additional security for the operator, they also protect the equipment against collisions. |

CAPACITY

|

WHEELS

|

BRAKE

|

STANDARDS

|

ERGONOMIC PUSHBUTTON STATION

|

MOTOR

|

OPTIONS

|

OPERATION

|

CONTROLS

|

FRAME

|

BEARINGS

|

OVERTRAVEL PROTECTION

|

GEARS

|

| Type | File | Size | ||

| Data Sheet | MR - Dual Speed Trolley (575V) | 175.7 Kb | View | Download |

| Data Sheet | MR - Single Speed Trolley -Connected to Single Speed Hoist (220V, 440V, 575V) | 197.17 Kb | View | Download |

| Data Sheet | MR - Single Speed Trolley - Connected to Adjustable 2 Speed (220V, 440V) or Dual Speed (575V) Hoist | 192.49 Kb | View | Download |

| Data Sheet | MR - Adjustable 2 Speed Trolley (220V, 440V) | 208.02 Kb | View | Download |