Articles

Jan 07, 2019 - How Will I Know If My Gearbox Needs Repair?

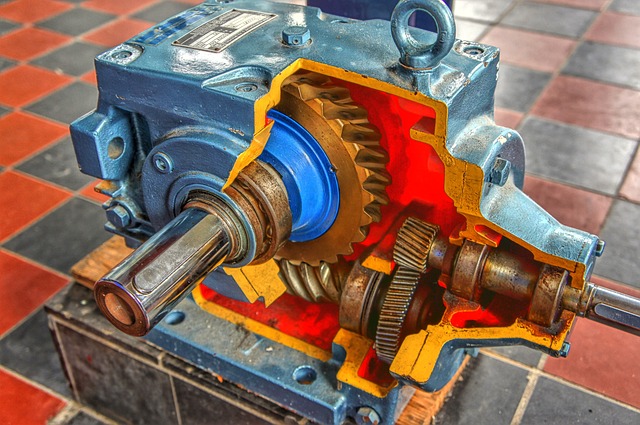

Gearboxes are used extensively in industrial settings to drive mechanical power and improve manufacturing productivity. These systems are sturdy, given the considerable amount of stress they must endure during the operational work cycle.

At Gordon Russell we provide professional services, repairs and supply parts for a wide range of gears from reputable, industry leading manufacturers including Bonfiglioli, Cone Drive and Radicon.

When you purchase your gearbox from a certified manufacturer, it will be engineered to withstand challenging environments, fluctuating temperatures and immense strains.

Whether your business is involved in the construction, farming, automotive, shipping, manufacturing or natural gas sectors, gearboxes are integral to your operations. In fact, these industries are known to invest an accumulated revenue of over 100 million annually in quality gearboxes.

Apart from the initial capital that you invest in a sturdy unit, there are several ways you can slash repair and maintenance costs - simply by keeping an eye out for certain signs that indicate your gearbox is damaged and needs attention.

Timely Maintenance Helps You Detect These Warning Signs

As durable as it is, no product is immune to depreciation. While they usually last for a longer period, overlooking your gearbox’s maintenance can cause your production process to come to a complete standstill - a standstill that could significantly backlog your operations by hours if not days. We urge you to conduct routine maintenance checks on your gearboxes, and keep an eye out for odd noises, peculiar smells, hitches in performance or temperature spikes.

Below, we’ve compiled a list of the most common gearbox issues that affect your industrial operations in the long run:

Overheating

This issue occurs when there is a lot of temperature variance between the shaft and the housing around the bearings, which can lead to serious damage to the gearbox. Such thermal instability results in extensive heat generation which may expedite the wear and tear of the unit. Sudden spikes in temperature indicate a serious underlying problem - the gearbox isn’t functioning as intended. One possible reason could be that the bearings are tightened beyond what is required. Another is that the lubricating fluid isn't cooling the device as it should.

Leakage

Oil leaks are one of the major issues associated with gearboxes and usually occur when there is a problem with the seal/gasket. Lower oil levels can significantly affect its operation, owing to the fact that the gears and components won’t be properly lubricated. If the seals around the shafts show signs of leakage, it’s possible that there is an ingression of moisture. Low oils levels eventually lessen the number of usable years left in your gearbox as it wears out the bearings.

Misalignment

This affects both the gears and bearings. One of the reasons why it occurs is due to the proximity of gearboxes to hot machinery or issues with installation. Moreover, if you unwittingly use the wrong gearbox for the wrong operation, you will further perpetuate this issue. Either way, misalignment can cause an undue force on the shafts, coupling and other components resulting in a potential unit breakdown.

Inadequate Lubrication

Your industrial gearbox is expected to operate under tremendous speeds and pressures. It requires the right lubricant to run smoothly. Skimping on that could mean that you will have to deal with a total shutdown of the system. In fact, it has been revealed that insufficient or incorrect lubrication contributes to industrial gearbox failure at least 90% of the time.

Choosing an incorrect lubricant for your gearbox machinery can lead to serious issues, especially to gears with higher sliding operations. Additionally, seal breakage can lead to oil leakage, corrosion due to ingression of contaminants and debris around the bearings.

Peculiar Noises

As a norm, your gearbox will produce regular sounds while in operation. What you need to watch out for is excessive clanking emanating from the unit.

As a result of regular exposure to progressive stress, power, and speed, gearboxes tend to produce peculiar clunking, humming sounds. This indicates an issue with the rolling bearings and can cause damage due to prolonged fatigue. The peculiar noises may indicate that your components are not functioning in tandem with each other.

Undue Vibrations

Industrial gearboxes need to function at high speeds and torques. This, in turn, causes reverberations through the unit - nothing that should concern you. However, if you find these vibrations increasingly over time, it may be as a result of fatigue, cracks, noise or failure of the shaft. What prompts this? A number of things, specifically incorrect mounting or insufficient support for your gearbox.

Trusted Repair, Maintenance and Inspection Services

We provide safe, reliable and professional repair / maintenance services for your gearbox. If you need an upgrade, choose from our quality industry-grade models, suited for your all your operational needs.

Our quality products find application throughout our resource based economy - Marine, Forest Products, Transportation, Mining, Oil & Gas, etc. With Mechanical Power Transmission and Railcar Handling our proven strengths, other products that include Hoists & Winches, Linear Motion, and Radio Remote Controls help broaden our scope of customers and expertise.

Contact us for a quote.

Web Design & Development by Web Masters Corp.